What does a longarm quilting machine cost?

"The value is more than the price you pay."

Major purchases and internet research go hand in hand. Buying a longarm quilting machine is no different. Price matters. Let’s find answers to what it actually costs to own a longarm.

Prices for quilting machines vary drastically. Buying a longarm is similar to purchasing a vehicle. You can go to a used car lot and pick out something that is budget-friendly, or you can go to the Mercedes dealership and custom order a luxury car built to your exact specifications. You can also go to the Chevy Dealer or the Honda dealer or whichever car dealership you like. You have so many options! Longarm brands vary in quality and characteristics just like cars.

Are you looking for a “starter” quilting machine? Perhaps you can find a used longarm, a mid-arm or a short arm for as little as $1,000 dollars. Maybe you want a new computerized longarm and you’re willing to spend $50,000. Quilting machines are available at these prices and everywhere in between.

Longarm, mid-arm, short-arm…. just what is a longarm? A quilting machine is a longarm if it has a throat space of at least 18” from the needle to the back of the throat. Longarms have been manufactured in sizes ranging from 18” to 36” inches. Usually, they are positioned on a carriage and rail system on a table that allows the user to move the machine over the surface of the quilt. When a longarm machine is placed on a stationary table it is called a sit-down quilting machine. A mid-arm has a throat space between 12”-17” and a short-arm has less than a 12” throat. The size of the throat is a big deal. It affects how big of a design can be quilted and how often you will have to advance the quilt.

Why are longarm quilting machines more expensive than sewing machines, mid-arms or short-arms? The adage “you get what you pay for” rings true with quilting machines as it does with most things. Some longarms are not just sewing machines that are large. An industrial quilting machine is made to withstand heavy-duty use and can last 40 years even if it is used every day. Industrial machines have bigger motors and more durable components. Other quilting machines use parts like domestic machines and are intended for hobby use. There is a world of difference. Of course, this affects the cost.

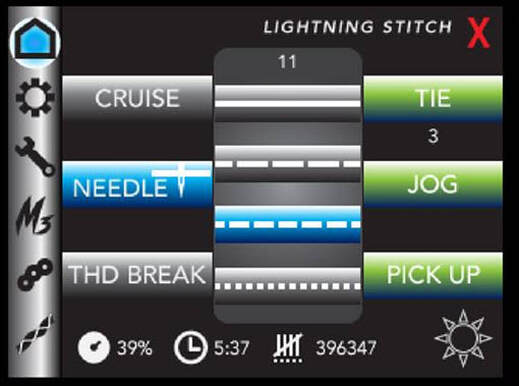

What else affects the cost of a longarm quilting machine? Options! Ask anyone who sells longarms what they cost and they will not be able to give you a quick answer. It always depends on which model and which options you want. Do you want a stitch regulator? Do you want the machine to be computerized? Do you want the light bar, the casters, the electric lift, the hydraulic table? Some companies include the table in the price, others do not. Do you want the machine delivered and set up professionally? Make sure that you know what comes with the machine and what options come at an additional cost.

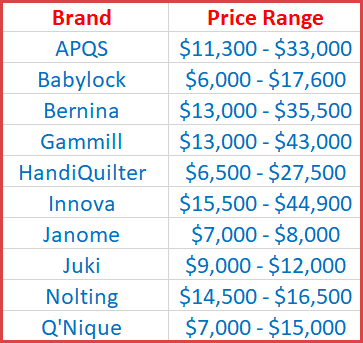

Below are links to several brands of longarms along with a range of prices. These prices are for a machine package and may include delivery or set-up. The best way to get an actual price for a certain brand of machine is to contact a dealer and ask for information about the models and options that meet your needs. If you want the machine delivered and set up for you, ask if that is available and for any additional pricing for those items. Request a written quote for that model or several different models if you aren’t sure which is best for you.

Prices above accurate as of August 2021

A good way to think about the cost of a longarm quilting machine is to consider the cost of owning the machine over the length of time that you will own it. It might be hard for you know just how long you will own a machine, but let’s give you a few scenarios.

Should you consider buying a pre-owned quilting machine? A new machine will certainly be more expensive but will offer some benefits. These factors may include a warranty, technical support from a dealer, training opportunities and the security of working with a business that takes care of its customers. Used machines can be a good choice if you are on a very tight budget or if you already know how to run and maintain a particular brand of machine. Used machines can be a steppingstone to see if you like the process of machine quilting. They are in high demand, so if you change your mind, you can sell it to another “newbie” or perhaps trade it in for a more expensive machine. On the flip side, not all used machines come with a warranty. If you buy from a private party, you will most likely be responsible for setting up the machine, learning how to use it and fixing anything that might be wrong with it.

How much should you spend? You are the best person to make that decision. Consider the value of the entire experience. The value is more than the price you pay. The value is what the machine costs to own versus what you get in return. Do you have a machine that creates stitches that you love? Is it easy to maintain? Can you upgrade it in the future? Do your friends recommend this dealer? Do you trust the salespeople? Do they have the expertise to help you accomplish what you want to achieve? Is support available even if you live a distance from the dealer? Those things create value.

- You buy a new industrial computerized quilting machine for $40,000 and it has no maintenance schedule. You used it for 15 years. It cost you $2,667 per year to own the machine.

- You buy a mid-arm for $9,000 and it has a maintenance schedule that requires you to send it to the factory every 18 months. You keep it for 3 years and spend $1500 on shipping and service at the factory. You sell it for $2000 because you realize that the throat space is just too small. The machine cost you $3,433 per year.

- You buy a $16,000 computerized hobby machine. You send it to the factory every 18 months for the 10 years you own it. The maintenance costs you $6000. That machine cost you $2,200 per year. While this is less than the cost of owning the industrial computerized machine, consider that you were without a machine for weeks at a time each time you sent it to the factory for its “spa treatment.”

Should you consider buying a pre-owned quilting machine? A new machine will certainly be more expensive but will offer some benefits. These factors may include a warranty, technical support from a dealer, training opportunities and the security of working with a business that takes care of its customers. Used machines can be a good choice if you are on a very tight budget or if you already know how to run and maintain a particular brand of machine. Used machines can be a steppingstone to see if you like the process of machine quilting. They are in high demand, so if you change your mind, you can sell it to another “newbie” or perhaps trade it in for a more expensive machine. On the flip side, not all used machines come with a warranty. If you buy from a private party, you will most likely be responsible for setting up the machine, learning how to use it and fixing anything that might be wrong with it.

How much should you spend? You are the best person to make that decision. Consider the value of the entire experience. The value is more than the price you pay. The value is what the machine costs to own versus what you get in return. Do you have a machine that creates stitches that you love? Is it easy to maintain? Can you upgrade it in the future? Do your friends recommend this dealer? Do you trust the salespeople? Do they have the expertise to help you accomplish what you want to achieve? Is support available even if you live a distance from the dealer? Those things create value.

Longarm machines have many different price tags.

You owe it to yourself to check out several choices before you make a decision.

Consider this before you buy...

“Do you want to buy your first longarm - or your last longarm first?”

You owe it to yourself to check out several choices before you make a decision.

Consider this before you buy...

“Do you want to buy your first longarm - or your last longarm first?”